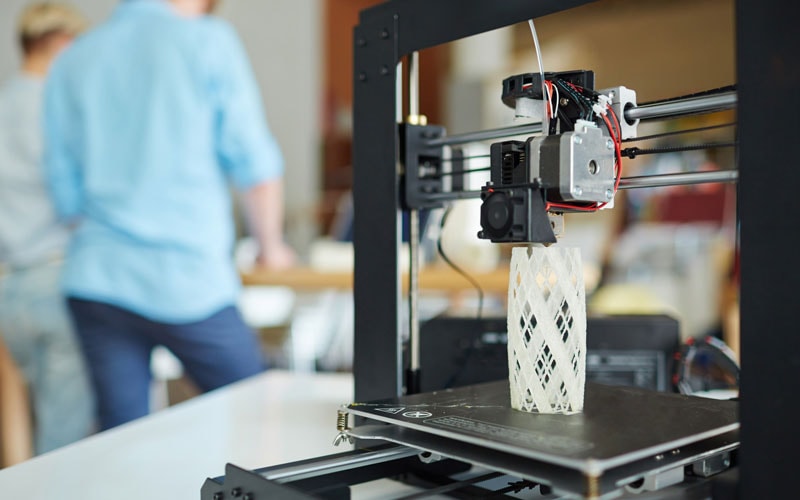

Did you know that more than 2 million 3D printers were shipped to customers in the year 2020? The 3D printing process is changing the ways in which people produce and manufacture goods thanks to the wide varieties of 3D printing material and the myriad of options you have for things to manufacture.

It is becoming increasingly clear that 3D printing is becoming the go-to option for manufacturing goods, but there are some serious 3D printing mistakes that you need to avoid if you want to produce flawless goods on a consistent basis. Little things like monitoring 3D prints go a long way towards producing high-quality prints.

If you’re worried about the mistakes that you might make when you’re starting out with 3D printing then you’re in luck. You’ve come to the perfect place to learn about the benefits of 3D printing and the things you should do in order to make the most of your 3D printer provider.

Keep reading this article for more.

1. Wrong Bed Level Height

The most important part of any 3D print is the first layer of that print. If the bed level height is incorrect then it will throw everything off for your 3D printing process and lead to a 3D print that is of much lower quality. You’ll find that making this mistake will result in wasted printing material as well as wasted printing time.

There are some 3D printer providers that have printers that don’t require manual leveling, but for printers without this automation, you’ll need to be extra careful with the bed level height if you want to produce quality prints the first time around.

2. Wrong Slicer Settings

Another thing that you’ll need to be careful about when it comes to 3D printing mistakes is getting the slicer settings wrong. This is the most common mistake when it comes to new users with the 3D printers behind only the wrong bed level height.

If you slice the file for your print in the wrong way or with the wrong settings then you’ll end up with a print that doesn’t look anything like how you want it to come out. Make sure that you monitor the slicer settings throughout the printing process for the best results.

3. Twisted Filament

The twisted filament is another common issue that people using 3D printers encounter. It is easy to try to place the blame on the 3D printer provider or the filament manufacturer but the truth is that this often happens due to user error. There are rare cases in which the manufacturer is to blame, but you’ll see that the filament is tangled as soon as you get done opening the packaging if that is the case.

Make sure that you’re not leaving the free end of the filament dangling or hanging in the air as this leaves it open to getting tangled with other filaments. If the filament gets twisted then you’ll find your 3D printer will struggle to produce a good print. If you try to print with twisted filament then your print is doomed from the start.

This is a mistake that you can’t afford if you plan to use your 3D printer for rapid prototyping. Check out this link at https://www.rapidpsi.com/prototyping/ to learn more about things to do in order to use your 3D printer for rapid prototyping success.

4. Lack of Support Materials

You should also ensure that you’re using support materials for your 3D prints if the print is fragile or a difficult type of print. These support materials are perfect for holding the print in place while it hardens and strengthens. Once the print is completed you’ll have no issues with removing the support materials.

You won’t always need support materials but some designs will turn out better when you use them. It is better to use that extra material to create support and produce a great print.

5. Poor Orientation

There are some prints that you might try with your 3D printer that requires a certain type of orientation rather than the usual 3D orientation. If you’re printing something with a large head then sometimes the best approach is to print your design in an upside-down way.

Trying to print oddly shaped prints in a normal way could lead to a failure and a waste of printing materials.

6. Unneeded Printer Upgrades

Sometimes people upgrade things for the sake of upgrading them. Doing this with a 3D printer is a sure way to end up making some bad 3D printing mistakes. It is important that you have a strong understanding of the design elements before you start upgrading or modifying your 3D printer.

Getting additional fans will change the bed level of your printer and there are other upgrades that lead to additional levels of vibration. These little things will change the quality of your prints.

7. Not Monitoring 3D Prints

If you’re going to dedicate your time and your printing materials to creating 3D prints then you owe it to yourself to do it the right way. This means that you should be monitoring 3D prints from the beginning of the process to the completion of the print. You need to be patient if you want to have success with the 3D printing process as it takes time.

The majority of 3D prints end up failing within the first five to ten minutes. Make sure that you monitor the print for that initial time period and then every 15 minutes or so until completion for the best results. Doing this will keep you from losing significant amounts of printing materials while also preventing damage to your 3D printer.

Take Measures to Avoid These 3D Printing Mistakes

3D printing is an amazing technology that is changing the way that companies and consumers are creating goods and tools. Getting a 3D printer from a 3D printer provider is easier than ever, but you need to make sure that you avoid 3D printer mistakes when getting started. Make sure that the filament doesn’t get twisted and that you’re patient during the printing process.

For more informative articles on a range of topics, check out our blog.